ABOUT

UK Engineering Company Providing Metal Pressing & Stamping Solutions Worldwide

About the Company

With historical genes traced back to 1919, Pre-Met Limited was incorporated in 1973 and has since grown into a quality assured metal pressings/ stamping, springs and assemblies, provider renowned for high quality and strong assurance on delivery, relied upon by global house-hold name OEM’s across Aerospace, Mobility, Transportation, Environmental, Medical, Electronics and Standards market segments.

With headquarters in Redditch, UK Pre-Met Limited turnover exceeds £6m per annum and our modern factory premises extend to over 50,000 sq ft, with a skilled workforce of over 60 employees.

Continuous Improvement and Innovation

Pre-Met is committed to improving the customer experience on a daily basis. Our company culture is about innovation and strict quality management. Lean manufacturing principles allow us to streamline all of our processes and departments to develop the optimal efficiency and quality for our customers.

Valuing Our Workforce

The success of Pre-Met relies on the excellent efforts of our workforce. We have nurtured a culture of innovation in our products and processes by encouraging employees to contribute at all levels of the company.

Furthermore, we invest in the skills and training qualifications they need to reach the highest standards in the engineering industry to benefit all of our customers. In-house training (LEAN) is provided in partnership with leading experts from the industry.

Mission

To continue to expand in the international market as a leading supplier and manufacturer of precision engineering for metal pressing and stamping.

To maintain a culture of innovation and continuous improvement to optimise all of our processes and products.

Core Values

Our success in the manufacturing and engineering industry is underpinned by four core values:

Commitment to Excellence

We strive to exceed expectations at all stages of the product life cycle.

Dedication to Teamwork

Working as a team, we can achieve greatness.

Employee Morale

The well-being of our team is central to our success.

Openness to Change

Innovation and agility are both essential to remain at the leading edge of this industry.

A History of Pre-Met

1973

Opened in 1973 and based in Maidstone, Kent. The two main markets Pre-Met supplied were high value accessories e.g. pens, cuff-links and lighters for Gucci, Dunhill etc. The other sector was the telecommunications industry with manufacture of metal switch components and connectors to companies like British Telecom, notably assisting in the development of the white BT431 socket.

Pre-Met soon established a niche as a provider of metal stampings and pressed components to the fast expanding

Telecommunications industry.

2005

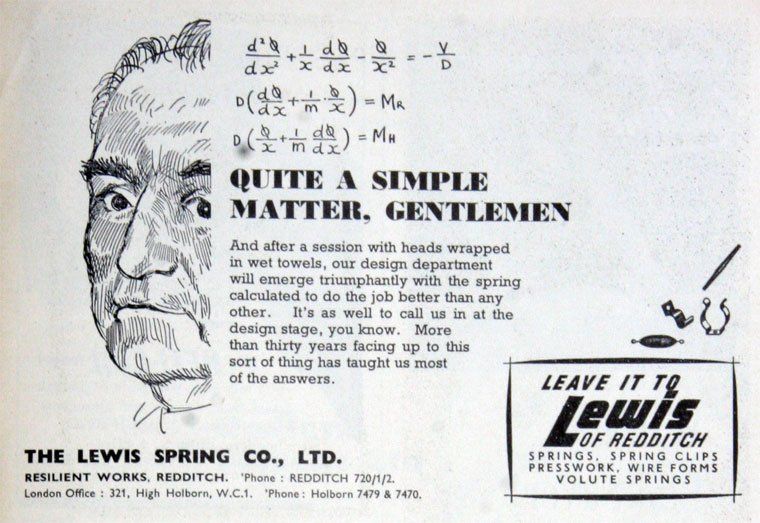

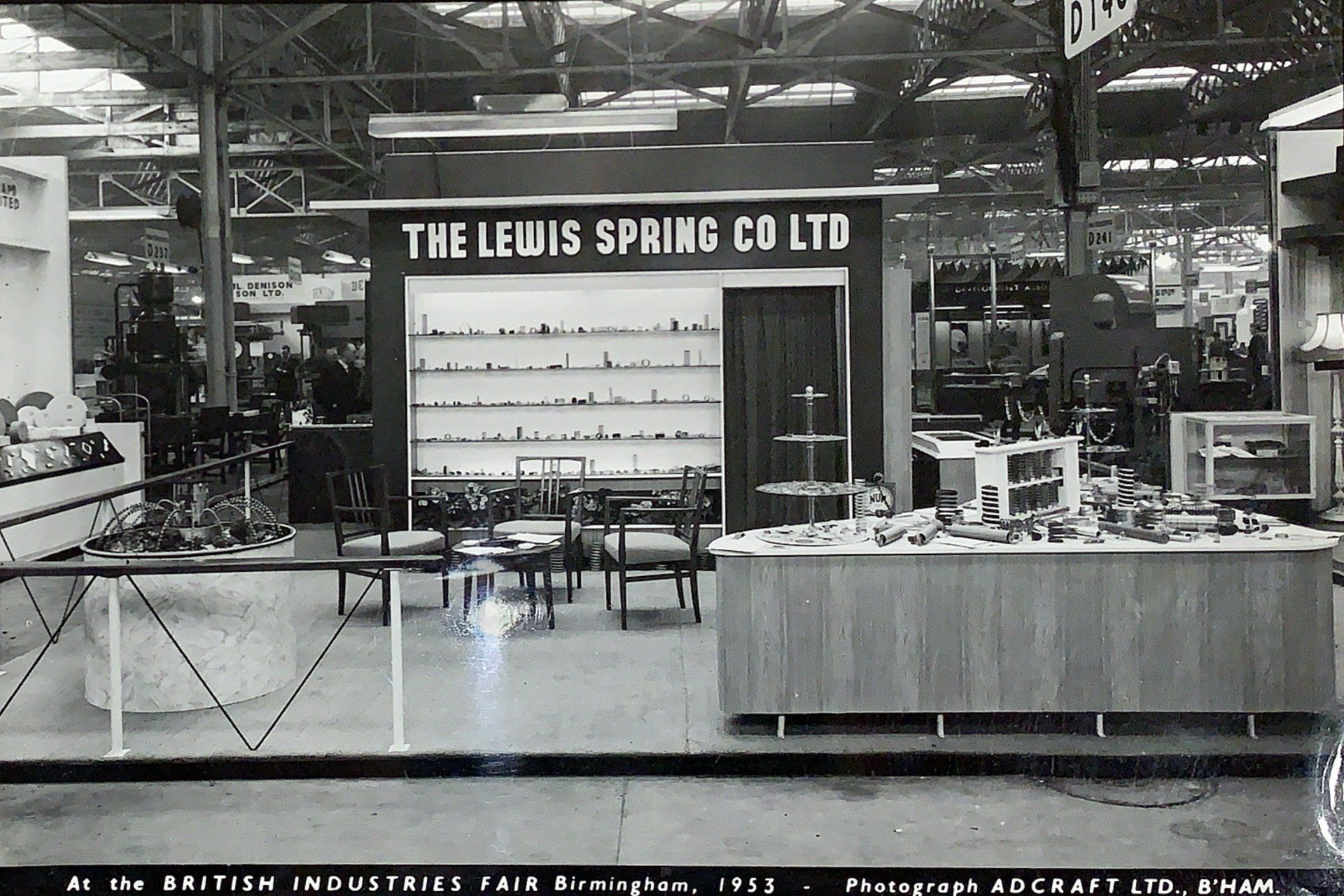

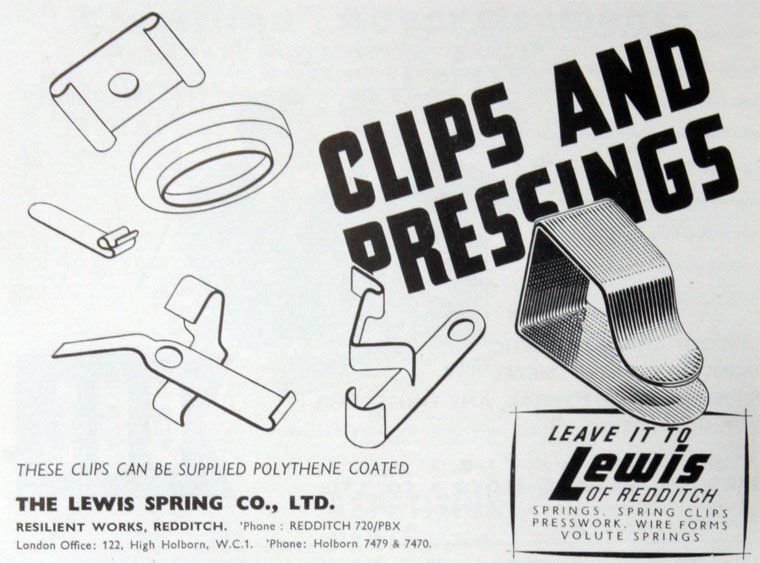

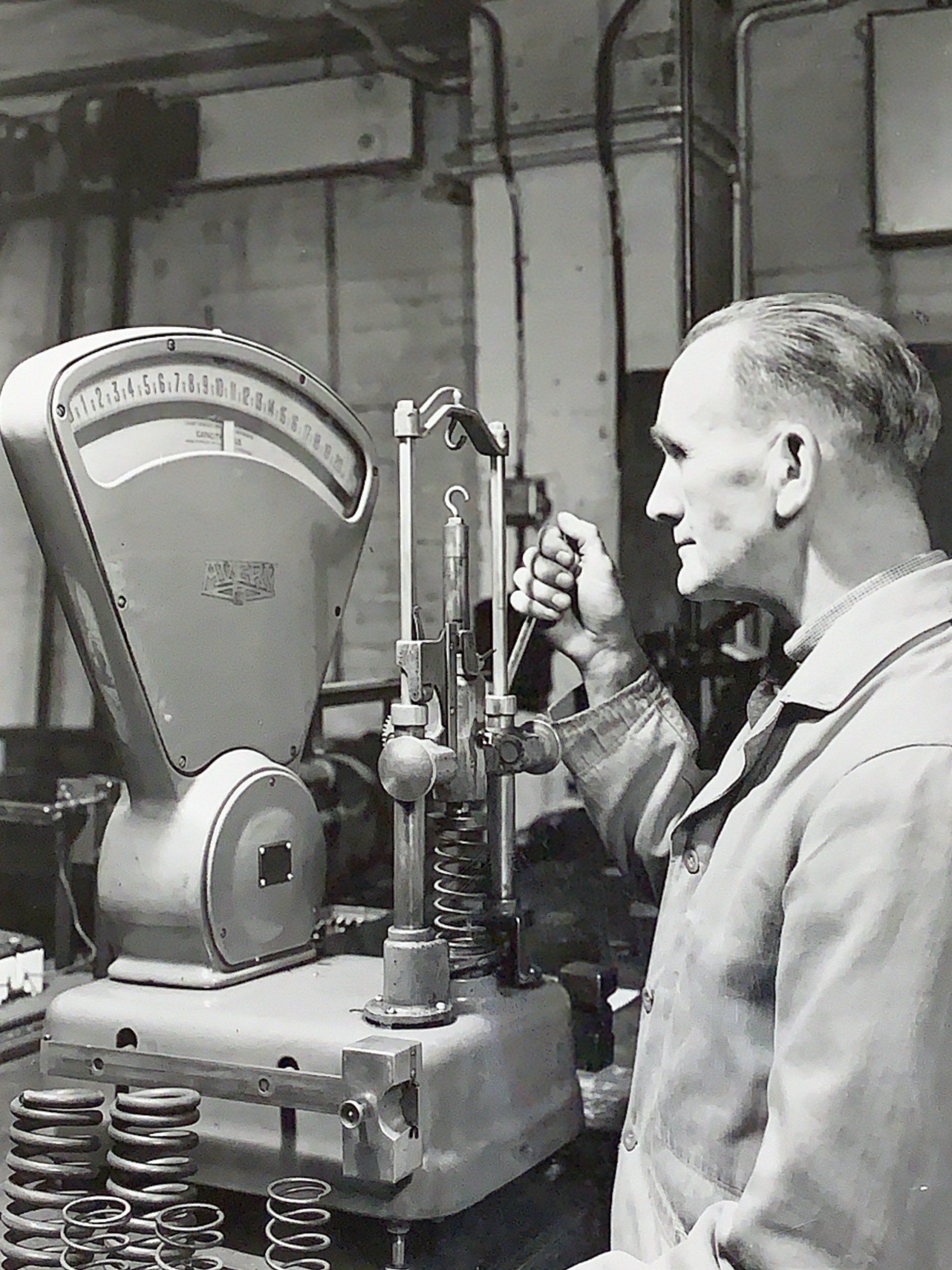

Jump forward to 2005, Pre-Met acquired the well-respected Lewis Spring in Redditch, established 1919. The two companies merged and became based on the current Lewis Spring site in Studley Road, Redditch. After a period of efficiency improvements, the now larger company streamlined manufacturing aligned with lean, 5S, Kanban and SMED best practices.

2008

2008 saw the acquisition of J.G. Ross, a low volume metal pressing and stampings business, established in 1961. Joining the Redditch site, it was mainly focused on the Aerospace and Defence market sectors.

2010

Pre-Met bought Mosses & Mitchell, a respected manufacturer of

professional audio, video jacks and patch bays (the No. 1 choice worldwide). Established in 1865 and originally specialising in the manufacture of insulation blocks for railway carriage suspension.

2015

Acquisition of Design Assemblies, established in 1965, and specialising in standard ceiling products e.g. cage nuts, compression rings and retaining clips.

2019

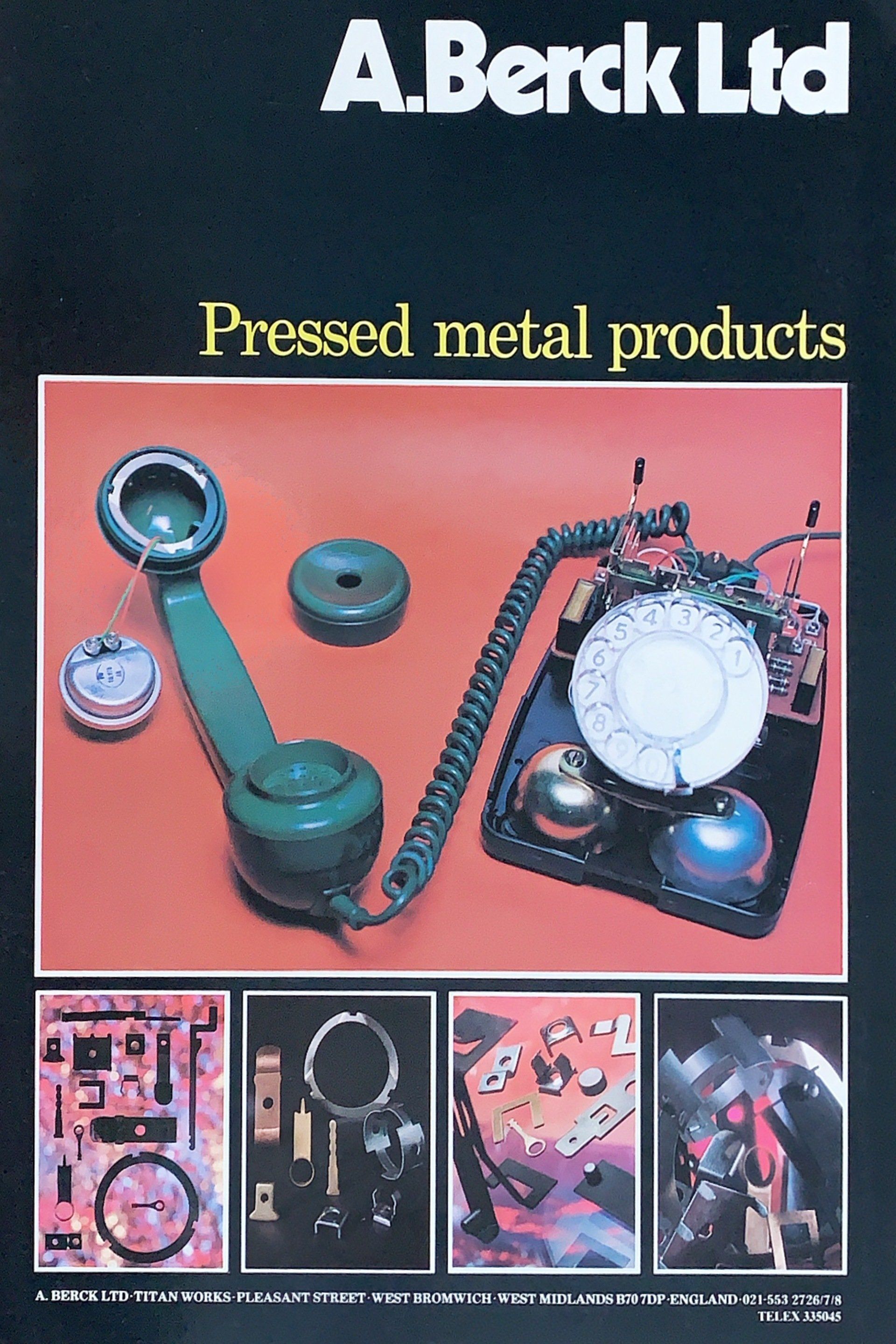

The biggest acquisition in Pre-Met’s history was Berck Limited, a company also producing high precision metal pressings and assembling components for different sectors worldwide. The acquisition of machinery led to increased capabilities in the

aerospace and automotive industries and Pre-Met became less dependent on outsourcing certain stages of manufacturing. This increased the speed with which Pre-Met manufactures new products from conception to production.

2021

Pre-Met successfully navigates the maze of Covid-19 disruptions and ongoing supply chain challenges, bucking the sector trend to grow in sales and strengthen its whole operation. A solid balance sheet, committed workforce, and long term supply base mean our customers can take comfort in the knowledge that we are here for the long haul.